Problems centre on reinforcement positioning at the ends of RAAC planks

RAAC that was properly manufactured and installed and is in good condition performs beyond its design strength, according to Loughborough University research.

Many experts have said RAAC installed up to the 1980s is time expired and should be replaced with John Roberts, the former president of the Institution of Structural Engineers, describing it as an inherently risky material that was mis-sold by manufacturers.

The Department for Education took the decision to close all schools known to contain RAAC last week just before the beginning of term and the NHS and other public sector organisations have also expressed concerns about the material.

Loughborough University has carried out insitu and laboratory tests on behalf of the NHS for the past two years to better understand how the material behaves under different conditions, the first testing programme since the BRE investigated RAAC in the late 1990s.

Concerns about the integrity of RAAC centre on the weak, porous nature of aerated concrete, which is susceptible to water leaks leading to reinforcement corrosion, cracking and delaminating. It also suffers from creep, a condition where the RAAC planks gradually sag, leading to water ponding on the roof surface.

But in an extended interview with Building today Chris Gorse, professor of construction management and engineering at Loughborough University, said this was not the primary reason why RAAC suddenly fails.

>> Read the full interview with Loughborough University’s Chris Gorse

>> CLC to set up expert panel to advise on RAAC crisis

He said: “We have found RAAC that is 40 to 50 years old and has suffered carbonation so the reinforcement is corroded and delaminating in some places, and it is variously cracked and in such a state of disrepair that you would think it is a real risk. But it can still stay in place and sustain loads, which is quite surprising.”

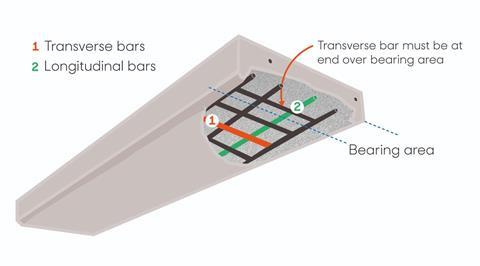

The most critical problems centre on the area supported by the wall at each end of RAAC planks. RAAC reinforcement consists of steel bars extending the length of the planks that are locked in place by a series of perpendicular, transverse bars.

Variable manufacturing quality meant the transverse reinforcement bars crucial for a roof’s structural integrity were sometimes positioned away from the bearing area at the ends of the planks, leaving the inherently weak aerated concrete to take all the loads.

Poor quality construction is a related issue where there is insufficient overlaps between the RAAC plank and wall to ensure a transverse bar is located over this bearing area. Gorse says these two issues are the main source of failure.

He said: “Whilst we have been concerned with the state that RAAC can get into, in the end the real weakness of the material is related to the way it has been assembled on site and the actual bearing properties.”

Failure of structurally compromised planks can be triggered by secondary issues including cutting through the reinforcement for maintenance reasons, extreme temperatures and overloading of the planks.

Gorse said he thought that the surveys carried out on schools to date are unlikely to have involved checking the integrity of the bearings as this necessitates an intrusive investigation which can be hindered by services installations, suspended ceilings and asbestos.

He added he doubted whether many surveyors were aware of problems with the bearings and that very few have asked how this should be done. This means that many of the surveys will need to carried out again.

No comments yet