Back in the 1930s, plasterboard was a revolutionary material and, according to British Gypsum’s Paul Campbell, it still is.

British Gypsum was formed in 1964, when a number of firms specialising in plaster production amalgamated. It is now a subsidiary of French firm Saint-Gobain, a corporation that had a turnover in excess of £24bn in 2005.

The founding firms started making plasterboard as an alternative to lath and plaster in housing in the 1930s. Residential is still a key part of British Gypsum’s market, as is commercial and repair and maintenance.

Housebuilders make use of the company’s metal-based wall systems while its sheet plasterboards are commonly used on refurbishment projects.

The firm has plants next to the UK’s major gypsum reserves in Kirby Thore in Cumbria, Robertsbridge in East Sussex, Sherburn-in-Elmet in West Yorkshire and Barrow-upon-Soar, Leicestershire.

Here, Paul Campbell, the firm’s commercial sector marketing manager, is quizzed about the state of the industry.

Which sector are you working in?

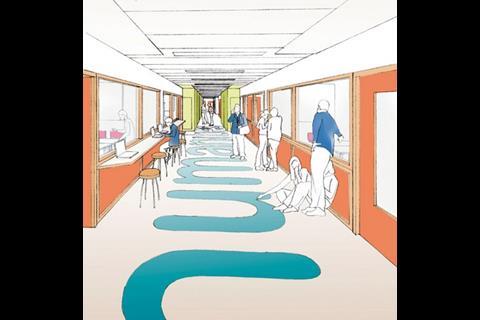

In the commercial sector. We’ve been seeing strong growth in health and education, with PFI procurement and the Building Schools for the Future programme. Although we perform strongly in both of these markets, we are looking at greater penetration.

What are the main drivers in the business?

In the health sector, acoustic regulation HTM 08-01, which comes in later this year to supersede HTM 2045. This regulation makes meeting acoustic requirements increasingly onerous. We are also thinking a lot about cost-effective solutions generally, with one line of inquiry being how we can reduce the physical footprint of a plasterboard wall. Reducing overall width works against fire, acoustic and durability properties. Reconciling this is a real challenge for us.

What innovations are you working on now?

The schools market has always had a leaning towards heavy-duty materials such as blockwork, but it is also susceptible to commercial pressures to keep costs down. One of our main focuses for innovation is to produce a lightweight alternative to blockwork. Our heavy-duty board, Glasroc Rigidur H, allows GypWall Extreme to meet that challenge.

It’s been developed to meet HTM 69 requirements, and has high impact resistance when submitted to key and kick testing. We see it as a product that’s particularly well suited to the health and education markets.

Have you worked with consultants to develop bespoke solutions?

We like to have early involvement on all our projects, but examples of specific worked-up solutions would be developing the lining and partitioning specification for the Sage in Gateshead with Arup Acoustics, curved wall designs at Selfridges in Birmingham, and Southwell Minster School in Nottingham, where we were asked to develop an alternative to blockwork and came up with GypWall Extreme.

How are you approaching the issue of sustainability?

In terms of the carbon miles of our products, we have three manufacturing plants based here in the UK, supplying all of our clients’ gypsum requirements. The same is true for the plants run overseas by Saint-Gobain – so we aim to keep this to a minimum. In the UK, too, we are now using recycled gypsum from power stations – a by-product of the process of coal-fired energy generation.

What are your lead times?

The Rigidur H board has about a 10-day lead time, but most products have a three-day lead time, even when specified at volume. We have enormous warehouses. Through good logistical management, we have no problems meeting anyone’s product demands.

Topics

Specifier 16 March 2007

Healthcare and Education

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

Currently

reading

Currently

reading

What to wear on your walls

No comments yet