The fifth article in the Steel Insight series focuses on the key factors to consider when cost planning a steel-framed school, college or university building

01 | Introduction

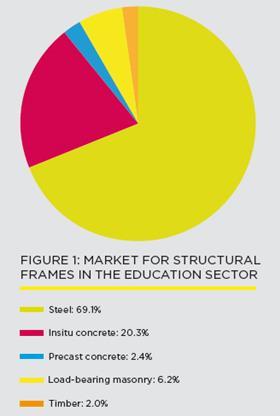

The education sector is a key sector for structural steelwork. The latest Construction Markets survey commissioned by the BCSA and Tata Steel shows that in 2011 steel frames accounted for 69.1% of all education construction in the UK compared to 22.7% for insitu and precast concrete and 6.2% for load-bearing masonry (Figure 1).

The first three Steel Insight articles (www.steelconstruction.info/cost_of_structural_steelwork) provided general guidance for quantity surveyors when cost planning structural steel-framed buildings. This included a detailed study of two typical commercial buildings in Article 3, to explore not only the cost but also the programme and sustainability benefits of structural steel frame solutions.

Article 4, published on 27 July 2012, marked a change in focus, considering the typical costs and key cost drivers of structural steel frames on a sector-specific basis. Following on from multi-storey buildings, this article considers education buildings. It expands the generic guidance of articles 1 to 3 by considering the typical design and construction characteristics of education buildings, the importance of programme, the key cost drivers for the sector and identifying the principal factors when using standard cost ranges during the cost planning of a proposed building.

It is important to recognise that the education sector covers a range of building types and functions, from primary school buildings to higher education institutions. As well as examining the typical frame considerations for different types of education buildings, the article also examines the issue of sustainability with respect to frame selection.

The article will conclude with the updated cost models for all building types, including updated location indices and a forward view of the market across the remainder of 2012 and into 2013.

02 | The education sector

While the education sector comprises a range of building types, forms and functions, common drivers for design and construction can be identified across the sector.

However, it is also important to recognise the distinction between school buildings (both primary and secondary) and other education buildings, such as those for further and higher education, as there are different drivers that impact on design and cost for each.

03 | School buildings: Typical characteristics

One of the key characteristics of the school sector is the existence of a number of common requirements that influence the design of the vast majority of buildings, such as classroom space, catering provision, library/resource space, indoor and external sports facilities, and so on.

While schools could be constructed through a range of different design solutions, successive government policy has promoted standardisation of design. For example, the recent James review supported the development of a “suite of drawings and specifications” that could “easily be applied across a range of educational facilities”.

The construction industry has responded by developing a number of standard solutions, such as Sunesis, ADAPT and PodSolve, which are generally steel-framed and can offer both reduced design and construction periods and reduced design fees.

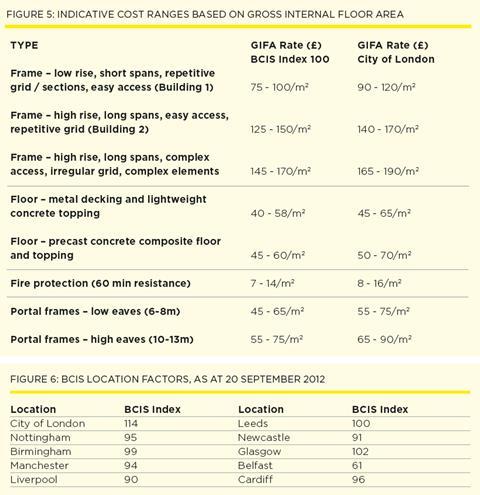

Given the common requirements, it is not surprising that many school buildings have very similar frame and overall building costs. Typically the frame cost range for both primary and secondary schools will be between £75 and £100 per m2 GIFA (BCIS location index 100). This is similar to Frame Type 1 in Figure 5 (low-rise, short-span, repetitive frame type).

However, as with all building types, there are a number of cost drivers that must be examined individually during cost planning to determine project-specific costs, such as site conditions, types of facilities provided and procurement route.

Programme is a key factor particularly for the education sector, where completion requirements are often driven by the academic calendar and it is common for schools to require new space for the beginning of an academic year. Where this is a requirement and the programme is challenging, a structural steel frame can offer advantages over other frame material options, through both the erection time of the frame itself, and also potentially through reduced construction periods for substructure, due to typically lighter frame weights.

04 | Further and higher education: Typical characteristics

When providing cost guidance on proposed projects, it is important to recognise that further and higher education buildings differ from school buildings in a number of key ways. Further education (FE) colleges provide facilities to post-school students of all ages, including vocational and work-related training in partnership with local employers. Higher education (HE) establishments, typically universities, provide a range of courses and qualifications and need to cater for both undergraduate and postgraduate students.

There is therefore a far greater variation in the FE and HE sectors in terms of function and facilities than for schools, so flexibility of space provided is key. A further characteristic is that FE and HE institutions will adjust courses to meet demand, so their offering, their requirements and therefore how they configure their buildings will vary from year to year. As the range of subjects taught is also greater than in schools, more specialist space is typically required, such as workshops, studios, laboratories and lecture theatres.

The demands of providing a range of functions, facilities and spaces, with their different spans, loadings, storey heights and internal layouts, can be accommodated easily with a structural steel frame solution. Structural steelwork can also effectively deliver the large volumes and spans associated with atrium spaces, which are often included within FE and HE buildings, and can provide flexible space that can be used for a range of functions, with opportunities for future adaptation.

Not only will FE and HE projects vary depending on the facilities provided, they can also vary quite significantly depending on their location. For campus-based sites, all the facilities will probably be in a single location, with central facilities such as learning resource centres or dining facilities provided in distinct buildings. For multiple site faculties, elements of a range of facilities would need to be provided in each location. The range of spaces required will be reflected in both the design and cost of the proposed facility, with regular grids, spans and higher degrees of repetition being the most cost-effective.

A further recent trend in the sector has been the increasing importance of architecture and design quality, particularly as institutions are increasingly competing for students, whether school leavers, international students or day-release students already in employment.

The impact of the different factors described above results in fewer opportunities in FE and HE projects for the use of standardised systems/designs. Consequently, standard steel frame cost ranges will vary depending on the type of building being provided. For a low-rise, short-span and repetitive frame, frame costs for FE and HE buildings will be typically as per Frame Type 1 in Figure 5 (£75-£100 per m2 GIFA at BCIS location index 100). However for high-rise, longer span or more complex buildings, reference should be made to the cost range for Frame Type 2 (£125-£150 per m2 GIFA at BCIS location index 100), although some functions, such as lecture theatres, will sit outside this range.

05 | Key frame cost drivers for education buildings

While the standard cost ranges for structural steel frames are a useful tool, it is also important to consider a number of project specific factors throughout the cost planning process.

Location and site constraints

These are key cost drivers for all building types, as the specific site will directly impact on the proposed building, influencing both the achievable design and the costs of construction. The characteristics of a proposed site will vary significantly for an education building in a tight city centre location from a building on a previously undeveloped or unconstrained out-of-town, suburban or campus location.

Site configuration will impact on the building design in a number of areas, including floor plate configuration, grid and building height. It can therefore also be a key consideration when estimating the structural frame cost of schools, as a school building on an unrestricted site would typically be single storey; whereas a tight site may result in two or more storeys being required to maintain the minimum requirements of external space provision. This may have an associated cost impact both in terms of site logistics and a longer programme attracting higher costs for preliminaries.

A less constrained site, without the need to take account of adjacent buildings, can also enable a more regular grid to be set. More repetitive structures will be more cost-efficient both in terms of material cost and on-site erection, so the extent to which a proposed building is influenced by factors that reduce the level of repetition needs to be assessed during cost planning.

It is also important to identify if the proposed construction works are on an occupied site, which is common for education projects. An occupied site will typically require restrictions to working times to limit noise, which may attract additional cost for preliminaries and/or impact on programme.

Facilities

The facilities to be provided should also be reviewed during cost planning; as previously highlighted, while the majority of schools will need to provide similar facilities, a consideration as to the proportion of each type of space required should be made, as this will often directly impact on the developing structural frame design. For example, projects with a range of different types of space (teaching, atrium, hall, workshops, and so on) will have different grid and loading requirements throughout the project compared to an all-teaching facility with very regular grids and loadings. The facilities mix is a key cost driver for FE and HE buildings due to the high variance in types of facility that might be required, which may make the proposed building significantly different from those considered in standard ranges.

Standardisation

Alternatively, if the proposed building design lends itself to standardisation and it is proposed at an early stage to use a standardised or specialist system, then the standard cost ranges based on a traditional build are unlikely to apply. In this case, advice should be sought from the supply chain during cost planning to ensure that estimates are not only based on the system proposed, but that they also take account of current market conditions and order books.

Partnering and framework arrangements

It should be noted that these are common in the education sector and that costs may therefore already be set out with one or a number of contractors for different types of project. Benchmarked or typical cost ranges based on projects tendered in competition could differ from the market conditions in which the framework was established. Pricing from the framework should therefore be reviewed and incorporated during cost planning if this is appropriate to the proposed scheme.

Programme

Furthermore, while programme is a consideration for all construction projects, it tends to be a key driver for education projects due to the constraints of the academic calendar and the common requirement for new or refurbished space to be provided to coincide with the beginning of an academic year. This can result in contractors and subcontractors having a large number of projects to tender and construct all with similar timeframes, which will inevitably mean that some projects are favoured by the market and others are not, and can result in some variations in pricing. Throughout the design process, it is important to liaise with the market and to ensure that sufficient time is given to tender periods; it is also important that the market is aware of the project and has factored it into estimating workloads.

Associated building elements

As with all projects, pressures on the design team during the development phase may tend towards only reviewing the comparative costs of different frame materials alone to inform decision making, but this is an overly simplistic approach, as the frame design will also impact on other elements.

For example, varying structural zones of different solutions and configurations will result in different floor-to-floor heights, which will impact on cladding costs, and different frame weights will also have an impact on the design and cost of the substructure.

Specification and standards

At the early design stages it is also important to gain an understanding of the client’s required specification and any applicable standards to be met. For example, if aesthetics are important, consideration should be given to the extent of boxing-in required for a steel frame or whether a high-quality finish will need to be specified for any exposed concrete. For all frame types the method of acoustic attenuation will also need to be assessed and included in early cost estimates.

06 | Structural frame type and sustainability

The government has identified schools as a key element of its sustainable development strategy and a number of targets have been set as part of its aim for all schools to be sustainable by 2020. Similarly, for FE and HE institutions, sustainability requirements are often set by funding bodies.

Since 2005 all major new and refurbishment school projects must achieve a minimum BREEAM rating of Very Good. Similarly, the acceptable levels of operational carbon (emissions during the operation of a building) are set out in Part L of the Building Regulations and each revision of the regulations requires improvement from the previous standard.

During the early design stages, it is typical for cost exercises to be undertaken across a number of potential solutions to achieve the sustainability requirements for the project, whether driven by government strategy, Part L or imposed by funding bodies.

Using thermal mass

Thermal mass has traditionally been identified as a cost-effective method of reducing operational carbon by lowering the requirements for mechanical heating and cooling through the use of the building fabric, in particular the cooling of the building by the introduction of night-time purging (drawing cooler night-time air into the building to pre-cool the slabs, which is slowly released during the following day).

However, some recent analyses and publications have challenged the assumptions that, firstly, thermal mass makes a significant difference to operational carbon and, secondly, that thermal mass can only be achieved through the use of specific framing materials, such as concrete.

It has been demonstrated that it is not enough simply to expose the soffit of a floor slab and expect good thermal mass performance in a building. The removal of the suspended ceilings in two buildings configured for standard HVAC systems in the Target Zero project undertaken by AECOM and Sweett Group (www.steelconstruction.info/Target_Zero) showed that the expected reduction in cooling load through thermal mass was offset by an almost identical increase in the heating load from the additional volume of space.

Target Zero also considered the impact of different structural frame options in relation to operational carbon emissions, showing that there is less than 1% difference between the performance of insitu concrete, steel and precast concrete and composite steel frame types. This confirmed that it is the floor slab that contributes to the thermal mass of the structure and any contribution from the frame itself is negligible in comparison. Thermal mass is therefore independent of frame material.

It also supported research that proved the depth of concrete floor slab available for use in thermal mass strategies is actually quite shallow (75-100mm). Structural requirements will ensure that this depth of concrete is available in any building using a concrete floor slab and the inclusion of additional depth purely for thermal mass purposes could reduce the sustainability of the structure, as it would involve additional volume of materials, a heavier superstructure and potentially larger foundations to support the additional weight.

During the design stages, there are added factors to be considered when using an exposed soffit to exploit thermal mass.

Acoustic performance

This in particular will require assessment. Typically, the use of an exposed soffit will require the introduction of “softer” materials to help control reverberation, such as hung acoustic baffles or panels. While there will be savings from omitting the ceiling to expose the soffit, the requirement for separate acoustic treatment must also be considered during cost planning.

Aesthetics

Similarly, it is important to consult the design team to ensure that the aesthetic aspirations are understood at an early stage - it may be that an architectural finish is required to exposed areas of the slab or structure beyond the finish normally specified, which will attract additional cost.

Technological developments

Consideration should also be given to other ways of creating effective thermal mass than the use of the frame and floor structures - for example, phase change materials (PCMs), which are capable of storing and releasing large amounts of heat or coolth at a relatively small temperature change. Examples include solid PCMs, which can be applied to boards positioned around the building, and the addition of thin suspended precast concrete panels to a steel frame.

Embodied carbon

When assessing the relative sustainable performance of different structural frame options, it is not only operational carbon that should be considered. Target Zero demonstrates that there is a significant difference in terms of embodied carbon emissions between different frame materials.

Embodied carbon assesses the carbon dioxide emissions over the whole life cycle of the building, including end-of-life considerations but excluding the operational carbon occurring during the building’s use. A significant proportion of a building’s embodied carbon is in the substructure and therefore the impact of frame choice on substructure will also impact on the embodied carbon.

For the school building considered, Target Zero concluded that a composite steel frame delivered the lowest embodied energy for both the substructure and frame, with benefits seen particularly in the substructure compared to a concrete frame due to lighter steel construction. Indeed, Target Zero identified that an insitu reinforced concrete structure had an 11% higher embodied carbon impact compared with the base case of a steel frame with precast floor slabs, while a composite steel structure and deck had a 3% lower impact than the base case.

07 | Summary and conclusion

Steel frames bring a number of advantages to the education sector, providing a range of spaces, loadings and spans in an efficient, economic and time-sensitive manner. Research also suggests they have sustainability advantages over other frame types, such as reduced embodied carbon.

It is important that the key cost drivers for the sector are understood in order for realistic cost plans to be produced during the design and early stages, when a number of frame options may be under consideration. This should include not only a comparison of frame costs, but also consideration of the impacts on associated building elements, such as substructure, cladding and services.

08 | Cost model update

Steel Insight Article 3 analysed two typical commercial buildings to provide cost and programme guidance when considering the options available during the design and selection of a structural frame.

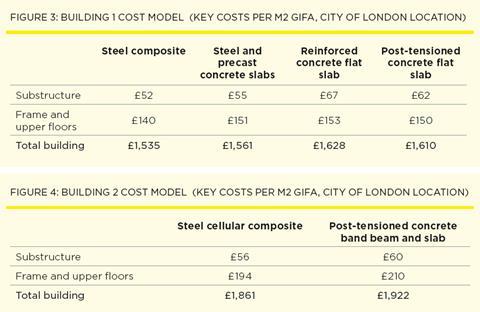

Building 1 considered a typical out-of-town speculative three-storey business park office with a gross internal area of 3,200m2 and a rectangular open-plan floor space. Cost models were developed for four frame types: steel composite, steel and precast concrete slab, reinforced concrete flat slab and post-tensioned concrete flat slab.

Building 2 considered a speculative eight-storey, L-shaped city centre office with a gross internal area of 16,500m2 and a 7.5m x 15m grid. Cost models were developed for two frame types, steel cellular composite and post-tensioned concrete band beam and slab.

Steel Insight Article 4 reviewed the May 2012 Business Innovation and Skills (BIS) material price indices and concluded that, although the figures showed some movement in material prices since 1Q 12, these supply cost changes were not being widely reflected in tender returns, both in terms of small increases in ready mix concrete and precast concrete products and in terms of a small fall in the price of fabricated structural steel.

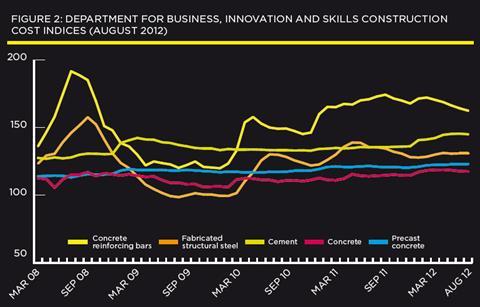

As Figure 2 shows, across 2Q 12 the indices for all materials have generally remained constant, with the exception of concrete reinforcing bars, which have shown an approximately 6% decrease in material price since the last high point in February 2012.

A key frame pricing factor over the next quarter will be whether the historic trend of fabricated structural steel prices following concrete reinforcing bar prices, with a one to two month lag (as shown in Figure 2), will continue to be realised through a reduction in the price of fabricated structural steel, and furthermore whether this will be seen in project tender returns.

The reduction in the material price of concrete reinforcing bars shown in Figure 2 has also been reflected in recent tender returns; however, the reduction seen has been in the region of 2-3%, as the tender costs include fabrication and installation costs, which have not altered significantly across the same period. This reduction to the concrete reinforcing bar price has been reflected in the updated cost model tables for both Building 1 and 2 above (Figures 3 and 4); however, it has not resulted in any adjustment to the m2 GIFA costs for substructure or frame and upper floors for any of the frame options with the exception of the reinforced concrete flat slab frame for Building 1. For this frame type, the frame and upper floor costs have decreased from £155/m2 to £153/m2 and the total building cost has consequently decreased from £1,631/m2 to £1,628/m2.

Despite this cost reduction to the reinforced concrete flat slab option, Figure 3 shows that the steel composite beam and slab option remains the most competitive for Building 1, with both the lowest frame and upper floors cost and lowest total building cost. For Building 2, as shown in Figure 4, the cellular steel composite option has both a lower frame and floor cost and lower total building cost than the post-tensioned concrete band beam option, with lower substructure costs, a lower roof cost and a lower floor-to-floor height, resulting in a lower external envelope cost.

The difficult economic conditions affecting both the construction industry specifically and the UK and international economy generally are continuing to have a stabilising impact on structural steelwork tender returns, and very little movement has been seen in tender pricing levels across the last quarter. This is shown in both the structural steelwork cost table (Figure 5), where the cost ranges have remained constant, and is supported by the BCIS location factors, which have shown little movement to the selected range of locations across the period (Figure 6).

Looking forward to the remainder of 2012 and into 2013, it is difficult to see any imminent signs of market recovery: public sector cutbacks and the inability of the private sector to compensate for this fall in demand for construction suggests that lower levels of construction activity may well be seen across 2013. In these conditions, and with both material prices and labour costs continuing to be depressed, tender returns are likely to remain largely stable across the rest of 2012 and well into 2013.

Use of cost table

a) identify which frame type most closely relates to the proposed project, b) select and add the preferred floor type, c) add fire protection if required, and d) adjust rates using BCIS location factors.

Before using such “standard ranges” it is important to confirm the anticipated frame weight and variables such as the floor-to-floor heights with the design team to determine whether they are above or below the average and to adjust the rate used accordingly.

Similarly, all of the other key cost drivers of complexity, site conditions, location, function, logistics, programme and procurement strategy should be considered in turn.

New steel website goes live

The steel construction sector’s new website, www.steelconstruction.info, went live on 1 October.

The site, developed over the last two years by the BCSA, Tata Steel and the SCI, is effectively an online “encyclopaedia” for steel construction.

At the core of the site are over 100 interlinked, freely downloadable articles written by industry experts, covering best practice in design and construction with steel, including topics such as fire engineering, sustainability, design to Eurocodes and health and safety. There are also links to other articles such as the Steel Insight series and the Target Zero guidance on sustainable low and zero carbon buildings.

So if you wish to catch up on any of the past Steel Insight features, please visit www.steelconstruction.info

The Steel insight series

This article was produced by Rachel Oldham (associate) and Alastair Wolstenholme (partner) of Gardiner & Theobald. It is the fifth in a series that provides guidance on the realistic costing of structural steelwork. The next Steel Insight will appear on 21 January 2013. If you are considering using structural steelwork for your building, bridge or structure, we recommend an early dialogue with a specialist steelwork contractor. They can offer a range of support and advice, including budget estimates and value engineering. Steelwork contractors can be sourced according to project size and technical competency. This searchable function is available at www.steelconstruction.info

No comments yet